Plus One Robotics, a provider of advanced AI vision software and solutions for robotic parcel handling, today announced new custome...

Plus One Robotics, a provider of advanced AI vision software and solutions for robotic parcel handling, today announced new customer programs using Yaskawa Motomanrobots. These customer deployments are for Plus One’s induction and mixed depalletizing solutions.

![640 (1).jpg]()

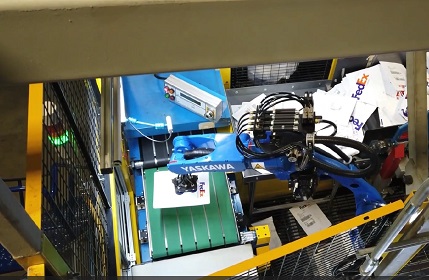

Plus One Robotics, working with Yaskawa, has expanded its AI robotic parcel handling solutions at FedEx

This deployment of Plus One and Yaskawa robotic solutions consists of 12 new induction systems acquired by FedEx Corp. This purchase builds upon the four existing robotic systems in use at the FedEx Express Hub in Memphis, TN. Additionally, Plus One successfully introduced its mixed depalletizing systems at the FedEx Reno, NV facility. Plus One’s mixed depalletizing systems will allow for easier, more efficient movement of cases from palleted shipments throughout the FedEx facility. FedEx will utilize Plus One’s human-in-the-loop software Yonder, allowing for remote supervision of the robots.

“The technology in these depalletizing arms helps us move certain shipments that would otherwise take up valuable resources to manually offload,” said Brian Marflak, FedEx vice president of Global Engineering, Research and Technology. “Having these systems installed allows team members to perform more skilled tasks such as loading and unloading airplanes and trucks. This has been a great opportunity for robotics to complement our existing team members and help them complete tasks more efficiently.”

“We’re proud that the Plus One solutions not only achieve the throughput necessary to fill the workforce gap experienced by all distribution centers, but do so with near 100% fulfillment accuracy,” said Plus One CEO and co-founder, Erik Nieves. “This not only keeps the operations running 24/7, but also provides benefits like ergonomics, safety, and the flexibility to handle the variance associated with seasonal shipping schedules.”

Key to Plus One Robotics’ effectiveness is its remote supervision software, Yonder, Plus One noted. Utilizing human-in-the-loop capabilities employees, or Crew Chiefs, can supervise multiple robots from any location allowing robots to handle a pick exception and return to autonomous operation within seconds. Utilizing Crew Chiefs to remotely supervise the robots helps organizations reduce downtime and creates a workforce multiplying effect that keeps parcels moving while freeing up on-site employees for other higher-value work. The software then uses this data to improve the machine-learning model for future picks.

“With Plus One’s incredibly fast image acquisition and processing, Yaskawa robots can achieve maximum production potential,” stated Doug Burnside, Yaskawa Motoman Vice President of North American Sales and Marketing. “This, combined with the intuitive Yonder remote supervisor support helps to efficiently and accurately manage robot operation for more fluid production.”

粤公网安备 44010602003952号

粤公网安备 44010602003952号