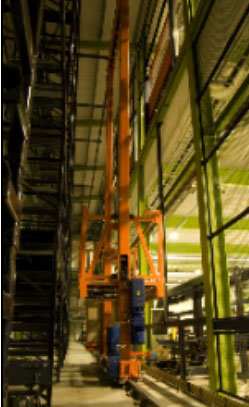

An 11.5m high crane serving 199 storage locations and automatically feeding components to three production areas o...

An 11.5m high crane serving 199 storage locations and automatically feeding components to three production areas over two floors has been designed and built by Excel Automation and is at the heart of a major investment programme at the Worcester factory of internationally renowned machine builder Yamazaki Mazak. And at Sixteen feed and retrieval points Excel has incorporated fast-reacting rising curtains that only open when the crane is at that position, this safety measure prohibiting access to the high-speed crane line during routine operation.

The new store came on stream at the end of March and in addition to shortening the production cycle for the build programme of the Mazak machine covers, it will expand the sheet metal processing capacity whilst also releasing more ground floor area for assembly of CNC machining centres and lathes to satisfy increasing demand for its products.

In designing the buffer facility Excel Automation had to accommodate storage of partly processed large flat sheet steel as well as smaller shaped items, all used to create the main covers of Mazak's machines. To satisfy the combined storage and production needs Excel built racking with a low-level facility for the flat steel pallets whilst shaped steel items are held in large purpose-built wire baskets.

To service storage needs as well as the twenty-two production feeds, the crane, which has a 1000kg load capacity, operates with racking on one side and the production areas on the other. This required Excel to build the crane so that its telescopic forks can extend either side of the main mast. The forks not only convey flat sheet steel pallets they also support the specially created storage baskets for shaped steel items.

Sheet steel arrives at Mazak's sheet feeder magazine that feeds three Mazak HyperGear 510 2.5 kW Laser cutting machines. Cut items are automatically retrieved by Mazak's Optopath sheet handling system, this incorporates 7200 vacuum cups allowing individual components to be lifted simultaneously from the sheet, eliminating the need for micro-joints and the time-consuming process of breaking individual parts from a complete sheet.

The cut components are transported by the Optopath to an Excel designed shuttle car with turntable then deposited onto a waiting pallet on the shuttle. This shuttle car moves from the Optopath deposit position to the crane interface point adjacent to the crane aisle, the turntable rotating on route to orient the pallet correctly for crane pick up.

The Excel crane, which has a horizontal travel speed of 130m/min., moves swiftly to the shuttle car to retrieve the loaded pallet and places it into the low-level racking to await call-out to feed one of four output trolley locations for bending. The pre-profiled sheets are fed into bending machines to create the shape needed to build the machine covers. After shaping, components are transferred to large baskets, also built by Excel, for return to the store. Their next move out of store is to the upper production floor, the crane which has a vertical speed of 30m/min delivering to one of twelve pick locations where components are taken to welding stations to complete the body-build programme.

On demand, the crane picks the storage baskets and transports them to one of two output chain conveyors to transfer the components to paint.

The Mazak buffer store is a fine example of how Excel has harnessed its many years of engineering expertise to create a fully automated crane and storage facility in a relatively small footprint, enabling its client to release more of its main area to production.

粤公网安备 44010602003952号

粤公网安备 44010602003952号