Hyster has provided a new fleet of forklift trucks and ReachStackers featuring the Hyster Tracker wireless asset management system ...

![Shanghai Hyster Forklift Manufacturing Co., Ltd.]()

Hyster has provided a new fleet of forklift trucks and ReachStackers featuring the Hyster Tracker wireless asset management system to support tough metal handling operations at the Port of Oxelösund in Sweden.

![]()

The Port of Oxelösund specialises in receiving big vessels and has a dedicated steel port. Here, metals, mostly coils, arrive at the port by trains, which are unloaded with a crane. Then, forklifts carry the goods to the port cranes, which load coils onto the ships.

When the port was recently looking to update its fleet, local Hyster® distribution partner in Sweden, Nordisk Truck-Trans and Hyster worked with the customer to create a total application-specific solution, including the Hyster Tracker telematics system.

“The beauty of Hyster Tracker is that it has a wide range of functions for effective fleet management,” says Dmitry Dubrovsky, Big Truck Manager for Hyster Europe. “This enables applications to utilise the features that are relevant to their specific operation, so they can see the bigger picture, gain insights, and reduce costs.”

![]()

For instance, at the Port of Oxelösund Hyster Tracker is fitted to Hyster® H32XM-12 and H20XM-9 lift trucks, with 32 and 20-tonne capacities, as well as Hyster® RS46-36CH ReachStackers to limit drivers, so only those who are correctly authorised can drive a truck during working hours. Drivers present a card to a reader by the steering wheel and the system then confirms whether the driver has the right license to operate the particular truck. This gives the busy metal handling application increased security.

“With Hyster Tracker, operators at the Port of Oxelösund also have a daily pre-use check to complete that appears via an in-cab display,” says Erik Progrebnjak, sales representative for the local Hyster® distribution partner, Nordisk Truck-Trans AB. “This check-up must be done before the truck is used and then at intervals after the vehicle has started.”

The Port can also see how the vehicles move on a map. This allows the operation to analyse potentially difficult traffic situations and see how the trucks are being driven.

“Increased productivity starts by knowing what your trucks are doing,” says Dmitry Dubrovksy. “With truck utilisation analysis, Hyster Tracker helps enhance fleet management and workforce productivity. It provides data-driven insights to help applications fine-tune the fleet size and composition to keep operations running efficiently.”

![]()

Hyster Tracker, which can be accessed on a Desktop portal or via a free app, also provides diagnostics and tracking which can help address problems before they arise by monitoring equipment performance.

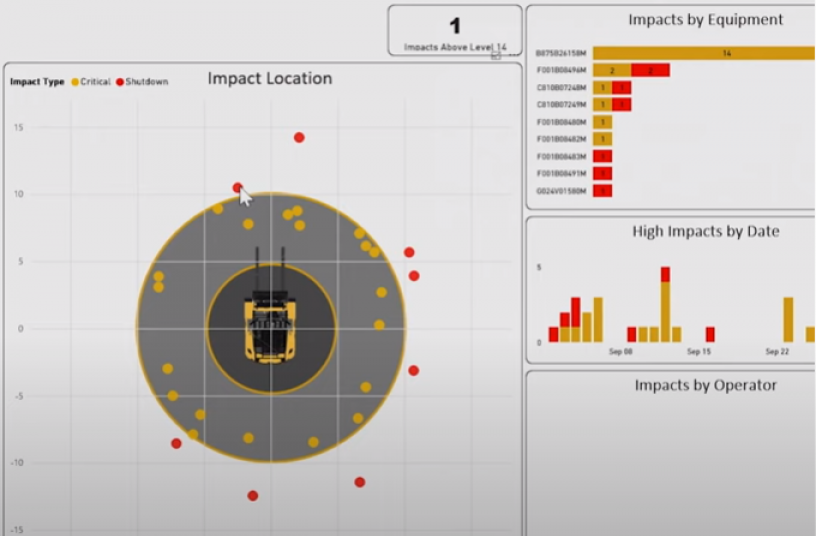

“Even though most drivers think they are efficient, Hyster Tracker can show the facts,” explains Erik Progrebnjak. “There are sensors that detect if an impact occurs. It also warns if the speed limit is violated.”

Hyster Tracker telematics also helps applications to streamline maintenance scheduling, conserve energy and reduce unnecessary equipment wear. Battery and tyre pressure monitoring add-ons are available to further help manage maintenance and costs and optimise equipment performance.

HYSTER is one of the world's leading makers of forklift and warehousing trucks. With 70 years dedicated experience in the materials handling industry and an exclusive network of dealers, we believe we can provide lift truck users with a unique combination of quality products and after sales service.

Our aim is to ensure that your trucks are available when you need them, allowing you to concentrate on your core business.

We hope that you find our site interesting, and look forward to hearing your comments.

HYSTER has been building lift trucks for over 70 years. The HYSTER story began in 1929 in the North American Lumber industry, with the supply of logging winches. The name HYSTER came from the cries of the workmen-"hoist'er".

The company then began to look for ways to improve general materials handling, and in 1934 built their first piece of mobile lifting equipment called a "cranemobile" which would later become known as the "karry krane".

The first HYSTER lift truck was built in 1935 and by the end of 1940's, HYSTER lift trucks, of various types could be found on ports and docksides, and loading timber yards throughout the U.S.A. and other parts of the world.

In the 1950s, HYSTER established its European headquarter in England, and then built its forklift manufacturing plants in the Netherlands, Scotland, Ireland and Italy, as well as in Australia. In late 1950s, HYSTER invented "Monotrol Pedal Technology" which controls both directions and acceleration. This technology was one of the most advanced technologies and has been used in forklift industry till now. With the developing of its business, HYSTER has built 14 manufacturing plants all over the world with a 16% world market share.

HYSTER Company is the first U.S. lift truck manufacturer to receive ISO9002 registration. The Testing Center which was built in 1960s in Portland is the biggest and best equipped lift truck testing center in the world. Today customers consider the word "HYSTER" and "lift truck" to be synonymous. We, HYSTER China with such a proud heritage will strive hard to make sure that doesn't change.

Shanghai HYSTER has been active in China for many years. Our commitment to serving our customers has led us to make a major investment in China. A totally new, award winning manufacturing and servicing facility became operational in 1999. Besides manufacturing a range of HYSTER products at this facility, the national HYSTER distribution and service network is managed from this centrally situated facility which is located in the Pudong, Shanghai industrial zone.

HYSTER China Headquarter is located in Jinqiao, Pudong Shanghai. The plant was formally opened on April 8th, 1999 with a 26,379m2 facility and over 100 employees. It adopts latest DFT (Demand Flow Technology) in its manufacturing and management system for 2-3 ton diesel trucks followed by one new range of 1.5-2.5 ton electric truck.

HYSTER China will use its worldwide resources to serve the domestic and multinational corporations in China.

粤公网安备 44010602003952号

粤公网安备 44010602003952号