An automatic lubrication system is available as an option, further exceeding the greasing intervals to more than 2.500 operating hours. The sideshift units comes with self-lubricating rollers on the lower side. Any kind of standard and special forks with fork lengths even well above 2.400 mm, hooked on or fitted with extra bolts, can be fitted to the robust and versatile pre-drilled fork carriers.

Industrial Application Sectors

MEYER High Performance Fork Positioners 6-25/26Gare being applied for various logistic handling tasks in various industrial sectors with palletized goods such as:

Logistics/Warehousing/Distribution (often performed by Third Party Logistic Providers)

Automotive (including both car makers as well as their suppliers)

Construction Industry / Building Material

Metal

Chemical Industry

Airports

![]()

MEYER High Performance Fork Positioners 6-25/26G are being applied for various logistic handling tasks in various industrial sectors with palletized goods.

Commonality and Convertibility

Most of the components of the 6-26G ISO 4 are identical to the 6-25G ISO 4 (that comes with an integrated sideshift): frame, cylinders, fork retainers, valve and shafts. This reduces the variety of wear and spare parts and offers identical options such as load backrests, valve and hydraulic protections, etc. Furthermore, it is possible to convert the 6-26G ISO 4 into a 6-25G ISO 4 and vice versa - the type of sideshift can be changed at a later time, giving maximum flexibility to fleet operations, rental fleets and end users with changing demands.

![]()

6-2516/18/20G: High Performance Fork Positioner with valve block sideshift and high capacities.

![]()

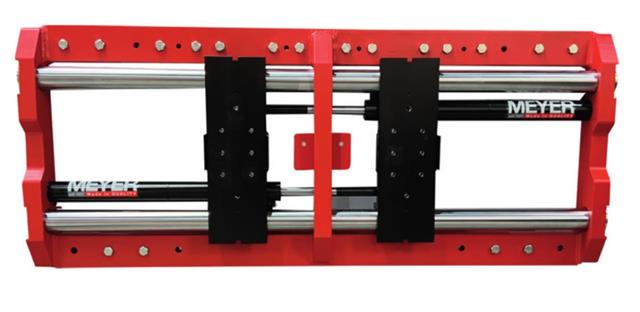

6-2620G: High Performance Fork Positioner. The new MEYER 6-26G ISO 4 is available from beginning of 2021.

The new MEYER 6-26G ISO 4 is available from beginning of 2021.

Wide Range of Loads: Wide Range of Fork Positioners

Forklift attachments manufacturer MEYER offers a wide range of fork positioners, with lifting capacities from 1,400 kg to 14,000 kg (3000 Lbs to 30,000 Lbs), available in sideshifting and non-sideshifting versions.

Fork positionersallow the adjustment of fork distances in regards to the load to be handled.

To sum up, the typical advantages of fork positioners are linked to faster and more effective operations and to a reduced load and pallet damage.

Still, the main advantage is given by the great benefits to the operator safety:

easy fork spread adjustment directly from the lift truck driver seat;

easier handling of pallets with varying dimensions;

increased work safety, avoiding driver injuries caused by manual fork moving.

粤公网安备 44010602003952号

粤公网安备 44010602003952号