Occupational health protection has been an important topic in industrial companies, distribution centres and in the retail sector in...

![Linde (China) Forklift Truck Corp., Ltd.]()

Occupational health protection has been an important topic in industrial companies, distribution centres and in the retail sector in the last years. With a wide range of standard and optional safety features, Linde Material Handlinghelps to prevent accidents with forklift trucks, protect the health of employees and save significant follow-up costs.

![]()

How can the new distancing rules be effectively implemented without disrupting work processes? Linde Material Handling provides a smart answer to this question with the Secure Distance Vest.

The latest safety feature from Linde MH is the Secure Distance Vest, an innovative wearable to effectively implement the new distancing rules without disrupting work processes. It continuously monitors the individually configurable minimum distance required between employees. If they get too close to each other, the vests emit alerts in the form of flashes, warning tones and vibrations. To do this, they use extremely reliable and accurate ultra-broadband technology, which works even through walls, shelving and gates. A further advantage is that no additional technical infrastructure is required; as soon as employees have put on their intelligent clothing, they can fully concentrate on their work without having to constantly assess whether they are maintaining the prescribed distance. If a case of infection occurs in the company nevertheless, the - optionally available - additional "Tracking & Tracing" function makes it possible to find out who has been in the vicinity of the person who tested positive. In this way, companies can avoid having to quarantine the entire workforce. All data is deleted after four weeks at the latest. An alternative to the Secure Distance Vest is the Linde Distance Beeper - small, portable units which offer the same range of functions but are attached to the clothing, belts or by means of wristbands.

![]()

The Linde Secure Distance Vest and the flexibly usable Linde Distance Beeper provide auditory, visual and haptic warnings if employees come too close to each other - thus allowing the ability to freely work with maximum protection against infection.

The Secure Distance Vest and Distance Beeper were developed based on the Linde Safety Guard assistance system, which warns of collisions between industrial trucks and pedestrians in intralogistics environments. Statistics and studies repeatedly confirm that there are still considerable risks involved when pedestrians and forklifts operate together in confined space.

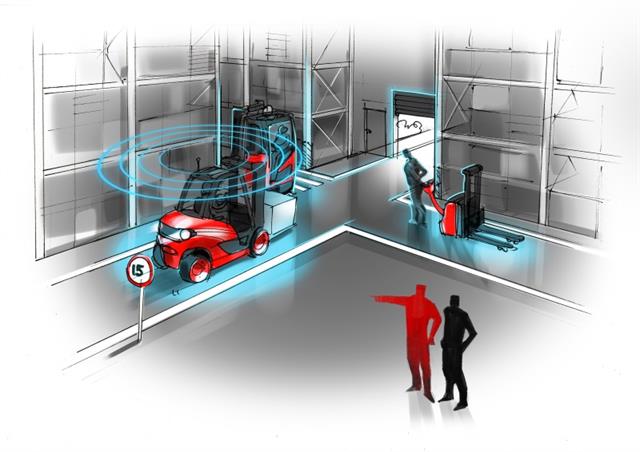

To prevent accidents the Linde Safety Guard assistance system alerts pedestrians and drivers of each other early on - even through walls and with an accuracy of ten centimeters. The pedestrian wearing an Interactive Warning Vest or a Beeper can "sense" the danger as the devices issue not only acoustic and visual alarms, but also vibrate.

Forklift drivers get the warning and in addition they can see on the truck display how many people are in the warning zone and from which direction they are approaching the truck. By using broadband radio signals in the 4-gigahertz range there is no interference with other networks such as WLAN, Bluetooth or RFID.

The Linde Secure Distance vest and Distance beeper can be easily converted to the classic functions offered by the Linde Safety Guard and conversely.

Another sensor-based assistance system from Linde Material Handling using broadband radio signals is called "Zone Intelligence". It helps fleet operators to mitigate potentially hazardous and costly situations by defining specific zones in warehouses and production areas in which the truck speed is automatically reduced.

![]()

The "Zone Intelligence" assistance system from Linde Material Handling allows fleet managers to specify zones within warehouse or production areas within which the vehicle speed will be automatically reduced.

"Zone Intelligence" is a module of the Linde fleet management system "connect" and exchanges broadband radio signals between stationary sensors and a sensor on the vehicle. To define the various zones, the fleet manager uses hall or plant layout maps which are uploaded to the computer via the "connect:desk" software. In the application, the various zones are configured using a graphic tool, and specific parameters are assigned to them. These include the range around a defined anchor point, the so-called Zone Marker, as well as, for example, the size of the braking area. The assistance system focuses on four fields of application: firstly, selective speed adjustment, which always takes effect when the truck approaches critical locations - for example, blind corners, crossings or intersections - that pose a general hazard potential. Secondly, it is possible to adjust the speed for areas with, for example, frequent pedestrian traffic. The third field is roller shutters or passageways, and the fourth is speed control on uneven ground.

![]()

The autonomous Linde R-MATIC reach truck transports palletized goods of up to 1.6 tons fully automatically to high-bay racks, storing and retrieving them independently at lifting heights of up to ten meters.

Cameras, sensors and laser technology also apply for the automated warehouse trucks from Linde Material Handling. On the horizontal level, the infrastructure-free contour-based geo navigation system guides the Linde AGVs safely and route-optimized through the various warehouse or production areas. The Robot Manager (supervisor software) receives, processes and transmits data in real-time and thus controls interaction with networked forklift trucks or other networked machines and devices.

A navigation laser permanently scans the surroundings within a 360° radius to orientate itself in space and to enable the Linde MATIC trucks to react to obstacles in real time. On the vertical level, sensors and 3-D cameras precisely scan the outline of a pallet, enabling it to be properly picked up and together with visual and audible warning devices, and emergency stops help prevent damage to racks, load carriers and goods.

The Linde MATIC trucks are scalable and flexibly adjustable to new warehouse layouts. Routes and driveways in the mapped area can be learnt quickly and easily.

Linde (China) Forklift Truck Corp., Ltd, the Asian base of Linde Forklift Truck was established in Dec. 1993 with a total investment of RMB 1.7 billion, which is the biggest forklift truck manufacturer in China with advanced technology.

Since entering China, Linde has developed a comprehensive network of sales and service providing advanced materials handling equipment and professional service. Linde provides the best solutions to improve material handling efficiency and reduce costs.

粤公网安备 44010602003952号

粤公网安备 44010602003952号