Every year, thousands of workers are seriously injured or killed after being crushed by mobile industrial equipment, particularly fo...

Every year, thousands of workers are seriously injured or killed after being crushed by mobile industrial equipment, particularly forklifts. The rapid growth in the materials handling industry, with the corresponding rise in machine/person interaction, has increased this risk substantially. The risks are increasingly underscored in health & safety compliance legislation, with policy dictates that must be actively mitigated. Failure to do so means directors and their executive can face serious penalties, including imprisonment, as a consequence.

Passive safety measures like high vis vests, safe operating procedures, blue-lights, reversing beepers, and reversing cameras, all play an important role in operational safety and prevent many accidents. However, because human error is inevitable, accidents will continue to occur. An active warning system provides a second layer of defence when passive systems fail. Actively warning the driver if they don't notice an inattentive pedestrian behind a reversing machine can make a lifesaving difference to everyone concerned.

![]()

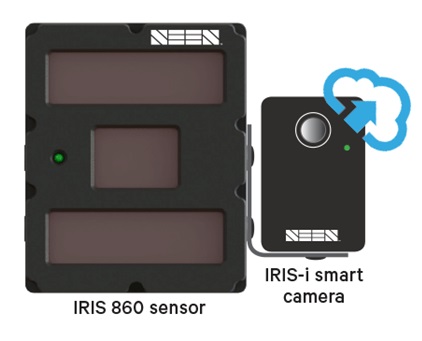

SEEN Safety's IRIS infrared sensorsactively, and selectively, detect reflective tape on high-vis safety apparel, transforming ubiquitous and passive high-vis PPE into part of an active pedestrian alert system for forklifts and other mobile plant. The sensors only alert within a designated detection area and can be easily configured to detect only when the vehicle is in reverse.

![]()

SEEN Safety's product roadmap also includes a smart camera clip-on module, branded IRIS-i, that automatically captures and logs detection event data, including images, and processes this as Cloud-based analytics - providing health & safety and operations management with evidence of how active controls mitigate their risks, while allowing them to make more informed decisions.

粤公网安备 44010602003952号

粤公网安备 44010602003952号