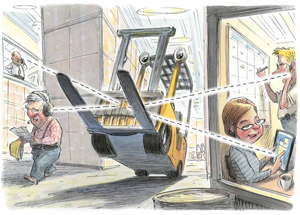

By tracking the speed and direction of travel of the lift truck, RFID can also position the equipment in three dimensions. If moving from one elevated pick location to the next, the operator need only apply the throttle and the system will determine the precise optimal speed to travel forward, lower, then elevate again, ending directly in front of the desired location.

“When an order or command is received, the operator simply navigates to the correct aisle and the lift truck takes over from there,” says Munger. “Through this technology, the WMS can actually manage the equipment, instead of relying on the operator to make each of these decisions about what he’d like to pick next. Even with the most experienced operators, efficiency can improve by as much as 25 percent on a given pick.”

Brandon Lutton, manager of product engineering for UniCarriers Americas Corporation, offers another example of the ways a customer can shape the lift truck to their needs. He recently worked with a customer to integrate onboard scales, which required extensive collaboration between the scale supplier, the onboard computer supplier, the bar code scanner supplier, the customer, and UniCarriers.

In the past, Lutton’s department primarily installed attachments, applied special paint colors, and installed aftermarket parts. These projects typically take two to three weeks from order to application, as compared to three months for the scale customer.

“The amount of changes made for this individual project were greater than what would typically be required for an entire model upgrade,” says Lutton. “I expect these sorts of projects to be more common in the future as customers demand fully integrated lift truck technologies.”

Tips from the scales

Lutton’s customer is not alone in benefiting from lift truck-mounted scales. The growing trend sees many lift trucks that can now bypass a stationary scale to weigh product on the move. When integrated with the WMS, this can add further visibility and accountability into product movement.

“This helps eliminate lost revenue created by shipping weight discrepancies, which can have a major impact on operation costs,” says Toyota’s Faiman. It can save on labor, fuel, and travel time by eliminating trips to scale stations or having to repack pallets to weigh items, while recovering floor space previously used for scale stations.

“Quite frankly I wish the onboard scale would be standard on every lift truck and not an option,” says McLeod, who says improved safety is an essential byproduct of integrated scales. “It allows a lift truck operator to know he’s operating within safe limits. This is a huge issue as I see it. A lot of the experienced people just do it by feel, but you need to know the capacity of your forklift and you should know what the load weighs along with its corresponding load center.”

As with each of the many lift truck technologies, a scale can be attached to the lift truck for the simple benefit it provides, or fully integrated with the customer’s other technologies for even bigger results. Although the latter option calls for a much more involved project, Craver predicts the combination of data from the WMS, onboard scale, fleet management, and labor management will become more common, in a trend he calls “data fusion.”

Hyster’s Dawley agrees: “There’s a gap there at this point, but I foresee these systems starting to come together, and a complete picture of what is going on in the facility will emerge.”

粤公网安备 44010602003952号

粤公网安备 44010602003952号