New assistance system from Linde MH facilitates rear-area monitoring and warns against collisionsWarning unit incre...

New assistance system from Linde MH facilitates rear-area monitoring and warns against collisions

Warning unit increases safety when reversing

Aschaffenburg/Germany, 21 May 2012 – In order to avoid damage to goods or buildings whilst trucks are reversing, and also to reduce the risk of accidents, Linde Material Handling (MH) is now offering a rear-area monitoring system as a customer option. The driver receives warnings via visual and acoustic signals in the cab as soon as objects appear in the monitoring area. If the situation becomes dangerous, the system also automatically reduces the driving speed.

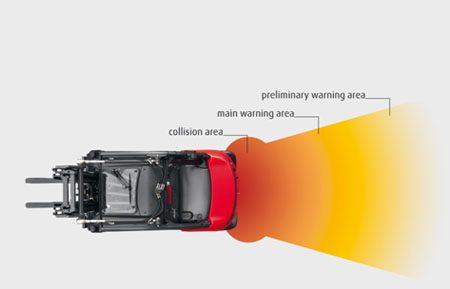

The rear-area monitoring system consists of two units, each with six integrated sensors at the rear of the forklift truck. There is also a central control module with visual and acoustic signal transmitters. The sensor units scan the area behind the truck, with the monitored area subdivided into three zones in a similar way to reverse parking systems in cars. Its range is up to nine metres, and the dimensions of the individual zones can be adjusted by the service engineer in accordance with customer requirements. By dividing the area into three zones, the driver should be warned at any early stage of any imminent collisions with objects or people. Zone 1 acts as a preliminary warning area. If an obstacle is detected in this area, the LED lights flash in the driver's cab and an acoustic warning signal sounds. Zone 2 is the main warning area; in this area, the LEDs flash in red and the warning signal sounds at shorter intervals. In zone 3—the collision area—the red LEDs illuminate permanently and the warning signal emits a continuous sound. For all three zones, an automatic reduction in the driving speed can also be applied. There is only a very small area beneath the rear of the truck that is not covered by the sensors. As well as rear-area monitoring, lateral monitoring is also possible.

Although the warning unit makes it safer for industrial trucks to reverse in situations where visibility is limited, it does not release the driver from his duty to drive responsibly and exercise due care and attention when reversing.

![]()

The graphic shows the functionality of the rear-area monitoring system from Linde MH: If an obstacle is detected during reversing, the system warns the driver via visual and acoustic signals. The intensity of the signal changes according to the distance from the object.

粤公网安备 44010602003952号

粤公网安备 44010602003952号