Energy-saving, precise and sensitive – the beating heart of the Linde truck has been going for 50 years.The fi...

Energy-saving, precise and sensitive – the beating heart of the Linde truck has been going for 50 years.

The first Linde truck with hydrostatic drive was unveiled to the public some 50 years ago at the 1960 Hanover trade fair. What nobody knew at the time was that the truck bearing the model designation Hubtrac H3K would lay the foundations for a success story that continues even to this day and that has made Linde Material Handling Europe's leading manufacturers of counterbalance trucks. A good portion of companies in many sectors swear by the red trucks bearing the white, curved Linde lettering.

The hydrostatic drive is at the heart of every internal combustion-engine Linde truck in the lifting capacity range up to 18 tons. It is inseparably linked to the trucks' sensitive, precise driving and lifting characteristics, as well as their economical fuel consumption and ease of maintenance. Even though the principle behind hydrostatic drive has not changed right up to the present day, the development engineers at Linde MH have made crucial technical improvements time and time again. With the introduction of the fourth generation of the Linde hydrostatic system, the truck manufacturer is asserting its position as a technological leader: two slow-running hydraulic motors have been integrated into the compact drive axle; these drive the drive wheels directly, i.e. without speed reduction gears.

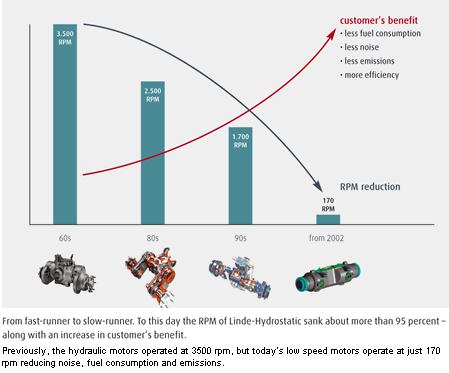

As Theodor Maurer, Chairman of the Management Board of Linde Material Handling, says: "We've never rested on our laurels. Existing knowledge and experience have always been regarded as the starting point in the quest for potential further optimisation of the drive unit and lifting hydraulics. The best example of this is the development stages of the drive axle: A speed of 3500 rpm was once required but today's low-speed motors operate at just 170 rpm. Progress of this kind requires a deep understanding of the system, something Linde has developed in the best way possible — through combining vehicle development and drive technology under one roof. This means that, looking ahead, our customers can be confident that by opting for the Linde brand they will be buying into technology that is both cutting-edge and extremely cost-effective".

The main components of the Linde hydrostatic drive are the hydrostatic pump and the two wheel motors. In contrast to hydrodynamic transmission, the hose connection between the pump and the wheel motors enables an optimal, flexible installation for the vehicle. Moreover, a hydrostatic gearbox does not need a clutch, manual transmission, gearbox or brakes, which is reflected in lower maintenance costs.

Since the 1970s, Linde MH has used axial-piston motors (characterised by high-pressure capability and adjustability) to convert the mechanical energy of the internal combustion engine into hydraulic energy. At around the same time, Linde MH moved away from bent-axis pumps to swash plate pumps and motors, and thus created the precondition for more compact installation dimensions, a longer service life and a very high power density. Since the mid-1980s, the swash plate pumps and motors have been used in all Linde truck applications – both in open (lifting hydraulics) and closed (traction hydraulics) oil circulation systems. Numerous other functions were standardised and integrated in the early 1990s, with the introduction of the 02 series of modern axial-piston machines of swash plate design. In 2002, the 39x-series of trucks represented a decisive breakthrough in terms of speed reduction, which led to a saving in the gear speed and therefore made the drive not only quieter and less prone to wear, but also more energy-efficient.

Many hydraulics experts were amazed at the power density and precision that were achieved with swash plate drives. In practice, swash plate drives proved superior to their radial-piston counterparts in which the main pistons, in contrast to an axial-piston pump, are arranged vertically (radial) to rather than in parallel (axial) with the drive shaft.

As Bernward Welschof, head of the Drive Technology development at Linde MH, says: "The essential factor behind every major development stage has been that the drive engineers at Linde MH are able to 'drill down', so to speak, into the vehicle itself. This is because Linde is the only manufacturer of forklift trucks responsible for nearly all components of the truck — from the accelerator pedal through to the wheels.

Furthermore, it is not only the hydraulic drive unit that is the product of the joint development of hydraulics and vehicles under one roof; the complete lifting hydraulics, including the electronics, steering and control levers are also products of this".

With the low-speed motor, Linde has now implemented the fourth generation of the hydrostatic system, which offers truck drivers a comfortable driving position, manoeuvrability and sensitive operation. At the same time, the operators benefit from low maintenance costs and high performance. Looking to the future, the drive engineers and vehicle developers at Linde MH already have further developments in the pipeline. Welschof says that, in future, "the hydrostatic system can act as a basis, for example, for connecting the drive principles of electric and internal combustion engines and offer users the best of both worlds".

粤公网安备 44010602003952号

粤公网安备 44010602003952号