Dedicated Transmission for exported combustion forklift

-

Zhejiang Zhongchai Machinery Co.,Ltd

普通商家 - Mode:Forklift Parts Manufacturer

- Area:ChinaZhejiangShaoxing

- Address:zhejiang

- All Products Enter Shop

Description

Parameters

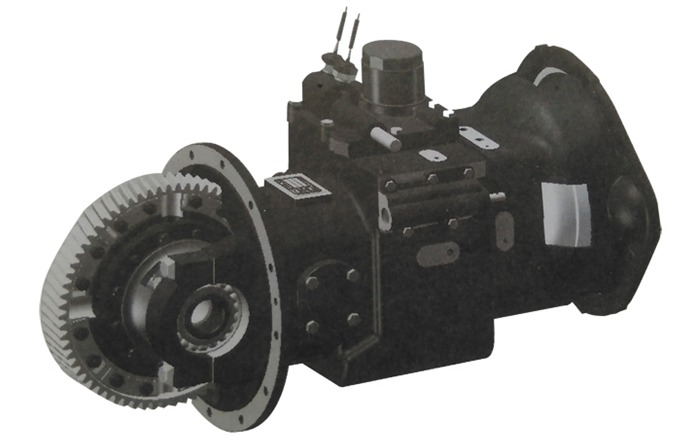

Product Picture

GYQX30 hydraulic transmission is developed for exported combustion forklift and domestic high-end customers.Products introduce technology from South Korea, using different kinds of design ways such as Finite Element Analysis, Material S-N Curve Analysis, Three-Dimensional Modal Test Analysis and Components Fine Design, etc. Application of Engine and Tor-con Matching Calculation Software, Gear&Bearing Application Analysis Software optimizes the design of transmission internal structure, lubrication system, hydraulic system optimization design and improves the performance of key parts such as Tor-con, oil pump, gear, clutch, micro valve, bearing. Thus it fully enhances the transmission performance and reliability.The commodity is mainly mated with imported engine, domestic engine conformed to the requirements of the export and provides high quality drive system for exported combustion forklift and domestic high-end customers.

一、Outstanding performance

1、The efficiency of transmission has increased 5% with lower fuel consumption of engine.

2、The noise of transmission reduced 3~5dB(A) (According to the JB/T 9720 Construction machinery—Bench test methods of transmission )

3、The thermal equilibrium temperature decreased 5~10℃ (According to the JB/T 3300 Counterbalanced forklift trucks – Testing method for whole machines)

二、Creative design

1、Patent designs of the internal structure. It contains 8 patented technologies, involving the component and structure of cast, clutch, gear, oil pump. The whole performance has been improved.

2、Optimized design of Tor-con with perfect one to one match with engine. It promotes the driving efficiency.

3、Advanced gear modification design with lower noise and higher comfort.

4、More reasonable braced structure with longer service life.

5、Separated design of Oil filter structure with more convenient maintaining.

三、Reliability assurance

1、Sufficient and dependable lubricating system

2、High quality imported component

3、Rigorous process control

4、Appropriative protective paint

四、Requirements focusing

一、Outstanding performance

1、The efficiency of transmission has increased 5% with lower fuel consumption of engine.

2、The noise of transmission reduced 3~5dB(A) (According to the JB/T 9720 Construction machinery—Bench test methods of transmission )

3、The thermal equilibrium temperature decreased 5~10℃ (According to the JB/T 3300 Counterbalanced forklift trucks – Testing method for whole machines)

二、Creative design

1、Patent designs of the internal structure. It contains 8 patented technologies, involving the component and structure of cast, clutch, gear, oil pump. The whole performance has been improved.

2、Optimized design of Tor-con with perfect one to one match with engine. It promotes the driving efficiency.

3、Advanced gear modification design with lower noise and higher comfort.

4、More reasonable braced structure with longer service life.

5、Separated design of Oil filter structure with more convenient maintaining.

三、Reliability assurance

1、Sufficient and dependable lubricating system

2、High quality imported component

3、Rigorous process control

4、Appropriative protective paint

四、Requirements focusing