Integrated Precision Cargo Weighing Improves Operational Efficiency

转载 2021-03-08 09:32 Tamtron Group Source: Tamtron GroupIncreased expectations for operational efficiency and meeting regulations while ensuring safety during operations are setting new demands for cargo weighing and the management of weighing data. When time and knowledge is money, it is essential to choose weighing solutions that will deliver reliable weighing data and support the companies' processes the best.

Weighing is often a vital part of the companies' or operators' business processes, delivering data for operations, reporting as well as invoicing. The weighing data also ensures safety - knowing how much the unit weighs can be utilised to improve loading and to meet the safety standards for the cargo and the carrier. While the weighing data needs to be accurate and reliable, the weighing equipment need to be endurable - they need to be designed to be robust, perform reliably and precisely, no matter the working conditions or the number of loads.

In addition, to accuracy, reliability and robustness, the demand for weighing while working and being able to utilise the weighing data simultaneously in all company's processes, is increasing. When weighing tens or even hundreds of units per day, the importance of integrating the weighing into the primary processes and being able to share the data throughout the process, helps companies to save money and work more efficiently.

- We have seen the increasing need for creating weighing solutions that are not only endurable and trustworthy, but also are built to support the customers' primary operations while providing precise weighing data. One customer of ours once said - weighing while working is like putting money in the bank, says Markus Ritala Sales and Marketing Director at Tamtron Group.

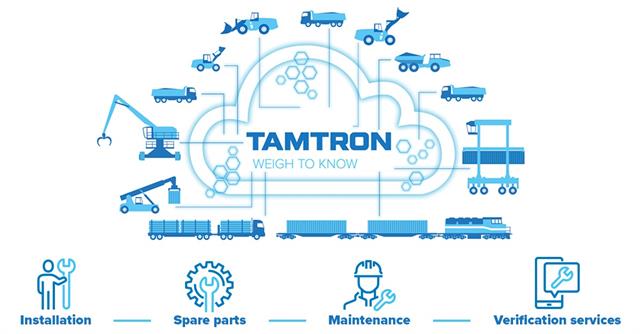

To meet the expectation for seamless weighing and dataflow, Tamtron has developed several scale solutions that can be installed to different cargo handling devices regardless of make.

Efficient cargo handling with forklift scales

Tamtron has developed two different scale models to fit forklifts - one for control weighing and the other for legal for trade.

Markus Ritalais explaining why two forklift scale models were needed:

- We wanted to support our customer's business processes when developing the Scalift-technology. While Scalift 100 is excellent for control weighing, our patented, Scalift 200 model, is not only legal for trade, but also meets the SOLAS requirements.

All Scalift models suit all kinds of forklifts. Weighing takes place while loading - it is accurate and fast, saves time by loading efficiently and you easily manage your weighing log. Weighing information can be transferred wirelessly or printed via RS232 port.

- With Scalift scales we can meet the expectations of extremely precise weighing while loading. Integrating weighing into loading process and by reducing unnecessary driving, one can minimize emissions and risk of accidents, improving employees' working safety, Markus Ritalacontinues.

Tamtron Scalift 100is designed for control weighing and suits all kinds of forklifts. The Tamtron Scalift 100 technology produces exact weighing results. The scale is rugged and informs the driver of overloads based on the given loaded capacities. It will improve operations' efficiency and productivity since weighing takes place while loading - it is accurate and fast, saves time by loading efficiently and you easily manage your weighing log. It is developed to organizations who require fast, accurate weighing and information management for their core business.

The legal-for-trade model Scalift 200is designed to meet the high performance and reliability demands of heavy-duty handling. With the Scalift 200 hydraulic pressure, height, velocity and acceleration of the forks are recorded during upwards and downwards manoeuvring, significantly improving the weighing accuracy and long-term stability. This patented technology eliminates the influence of mechanical friction, non-linearity and weighing tolerances caused by load positioned on fork tips. The dual tilt compensation ensures an accurate weighing result regardless of inclination of forklift mast and floor. This patented, type-approved scale also meets the requirements of the SOLAS regulations. The Scalift 200 is the ideal choice for applications, where extreme precision is requested, also for commercial use - such as steel mills, concrete yards, sawmills, and port operations.

Berner Koneet chose Scalift scales for their forklift trucks.

- Some forklift trucks have had scales that do not meet the criteria we set. We have then replaced them with Tamtron scales, says Matti Koljonen, Combilift Product Manager at Berner Koneet, and continues:

- We wanted to find a scale that meets the needs of our customers so that they are satisfied with the products. Easy to use and weighing accuracy are important things for the driver.

- Everything Tamtron has promised has been kept, and always on schedule. Yes, such a familiar and reliable partner is an important and integral part of our business, Matti Koljonen, Combilift Product Manager at Berner Koneet concludes.

Easy access to weighing data improves ports' container handling efficiency and safety

- Efficient cargo handling is vitally important in busy seaports where the degree of efficiency achieved to maximize cargo handling at the port area, quickens ship turn-round time and minimizes cargo-handling cost. Integrating the weighing as part of seaports' cargo handling processes, is necessity for any scale producer, Markus Ritalais clarifying.

- For customers operating in the seaports we offer type-approved, accurate, high-quality scales and modern weighing information management systems that ensure real-time access to the information, reports and operations monitoring. Efficiency in a nutshell, he continues.

Advanced and easy-to-use scales weigh containers according to the SOLAS regulations during normal operations without interrupting or slowing down the workflow at seaports or in container depots. Tamtron's Container Stacker and Straddle Carrier scales improve safety at seas, as the incorrectly reported container weight that can cause cargo to fall over is possible to avoid.

Type-approved Tamtron One Power Container Stacker Scaleweighs verified gross mass (VGM) of a container accurately (accuracy 1-2%) within the normal workflow and meets the requirements of the SOLAS regulations. One Power Container Stacker Scale can be installed in all types of container stackers. The weighing information can be transferred to operational use two ways: through integration into TOS or other systems or through weighing information cloud service. The scale is available with an advanced One weighing instrument or with a PC version that is possible to integrate into on-board PC.

Approved and tested Tamtron One Power Straddle Carrier Scaleweighs verified gross mass (VGM) of a container accurately (accuracy 0.5-2%) within the normal workflow and meets the requirements of the SOLAS regulations. One Power Straddle Carrier Scale can be installed in all types of Straddle carriers. The weighing information can be transferred to operational use two ways: through integration into TOS or other systems or through weighing information cloud service. The scale is available with an advanced One weighing instrument or with a PC version that is possible to integrate into on-board PC.

From scales to weighing solutions

- High-quality scale is the foundation for accurate and reliable weighing data. But how the weighing is integrated into the operational processes as well as how the weighing data is stored and shared to support the customers' business, is how we as a weighing solution provider can help our customers best. Recent years we have focused to improve the usability of our scales and offer the remote access to the weighing data - new digital solutions to get rid of paper receipts and documents, Markus Ritalais explaining how Tamtron has developed their weighing offering.

The weighing information transfers from Tamtron scale to operational use in real-time through connection to the weighing information cloud service or through integration into TOS, ERP or other system. Bi-directional data-communication enables container ID and VGM to be combined. From all Tamtron scales used at the seaport - container stacker scales, straddle carrier scales as well as from traditional weighbridges, the information can be collected into the same information management infrastructure where all transactions can be managed and monitored. With the information, operations can be optimized to be as fluent and efficient as possible.

- Tamtron's professional weighing equipment with solid connectivity and data management will help operators to meet the demands for transparency, traceability and ever-growing reporting liabilities. Reporting between co-operation partners becomes easier when the required information is available on one system, easily and reliably, concludes Markus Ritala.

Relevant Info

More- Unleash the Future of Power-HELI Heavy-Duty Electric

- Hangcha Canada Kicks Off Quebec Dealer Days

- Toyota Material Handling North America, Tailift USA to enter alliance

- Tyre overhaul boosts Ahlmark Shipping’s forklift performance at Port of Hull

- Combilift turns 100,000th forklift into €100,000 lifeline for children

- Impact Handling marks 15 years powering the UK with Cat Lift Trucks

- Toyota launches MyToyota Portal to revolutionise forklift fleet management

- Clark crossover forklift shows its strength at Duisburg Zoo

- Crown forklifts boost Decostar’s warehouse productivity by 18%

- Bobcat unveils first lithium-ion 3-wheel forklift in major electric push