Lift trucks are still the work horses of materials handling. For all the attention on autonomous mobile robots and other forms of...

Lift trucks are still the work horses of materials handling. For all the attention on autonomous mobile robots and other forms of robotics, nearly every DC uses manually operated lift trucks to receive goods, crossdock, build pallets for retail store replenishment, or for truck loading, with other duties in between.

![]()

Lift trucks also happen to be heavy pieces of equipment, weighing thousands of pounds more than the typical passenger car, and transporting loads that may exceed a couple of tons.

That’s why safe operation of lift trucks is such an important issue. According to the National Safety Council, in 2021, lift trucks were involved in 70 work-related deaths. Additionally, the U.S. Occupational Health and Safety Administration (OSHA) estimates that approximately 70% of forklift incidents could be avoided with proper safety training and policy.

As a result, proper operator safety training remains the most important facet of lift truck safety, which is why the Industrial Truck Association (ITA)makes operator training the focus of National Forklift Safety Day, which this year falls on June 13.

But assuming an operation has a solid training program in place, what else can be done to contribute to safer lift truck use? According to lift truck suppliers, sensor-based technology and alerting systems can help assist drivers in spotting hazards and be more aware of high-risk situations. The capabilities of these various “operator-assist” safety features continue to advance, going well beyond the days of simple back up horns and lights.

Some of these technologies can actively slow down or stop a truck in certain situations, and most will also alert operators audibly and/or visually. These technologies aren’t pitched as safety features, but they are seen as reducing the risk of incidents by making operators more aware of their surroundings and reinforcing best practices and training.

“It’s awesome to see these technologies coming in to enhance work environments,” saysBrett Wood, president and CEO of Toyota Material Handling North Americaand senior executive officer for Toyota Industries Corporation.

Sensing obstacles

DCs can be busy, noisy environments where even a well-trained operator might not see an obstacle left in an aisle or might have a pedestrian inadvertently walk into the path of the truck. Those are the types of risks that object sensing and alerting solutions help guard against.

![]()

Toyota’s SEnS Smart Environment Sensor Plus or “SEnS+” is an operator-assist system featuring truck slow down.

The latest advancement in object detection at Toyota Material Handling is its Smart Environment Sensor (SEnS), which uses a stereoscopic camera to detect pedestrians and objects behind a forklift during operation.

The system uses proprietary algorithms to distinguish between the types of obstacles in view, meaning it can tell the difference between a person or an object like a pallet or cone left in an aisle. SEnS is available as an add-on kit for select Toyota lift trucks.

Toyota also offers SEnS Smart Environment Sensor Plus (SEnS+), an operator-assist system featuring truck slow down as an option for its 3-Wheel Electric forklift and its Core electric forklift. This system offers additional features besides notifications; it can control the speed of the truck in certain situations or slow down the truck for pedestrians or objects under certain conditions.

With dynamic zoning, SEnS+ adjusts the range of detection based on the speed and steering direction of the forklift. If the forklift is moving faster, the zone is expanded to account for potential, upcoming obstacles further away, up to 32 feet. Additionally, if the forklift is stopped and the system detects an object or pedestrian behind it, it automatically limits the truck’s starting movement and speed, even if the operator tries to accelerate.

Importantly, adds Wood, the ability of the stereoscopic technology to adjust to steering direction and speed allows the system to apply speed control in the path of travel, while avoiding false notifications of pedestrians near the truck but not in the detected range of travel.

Toyota also offers its System of Active Stability (SAS) to help prevent tip overs. It uses data from different sensors, including a yaw rate sensor, to detect unstable conditions. If needed, the SAS can automatically take protective action, locking the rear axle to reduce the possibility of tip over.

Pair with telematics

Multiple lift truck technologies can contribute to improved safety, from telematics systems that track safety incidents to sensor-based object and pedestrian detection features, notes Jim Gaskell, director of global automation and emerging technologies at Crown Equipment Corporation. While sensor-based solutions have advanced rapidly, don’t forget about the value of telematics for tracking incident trends and digitizing safety checks.

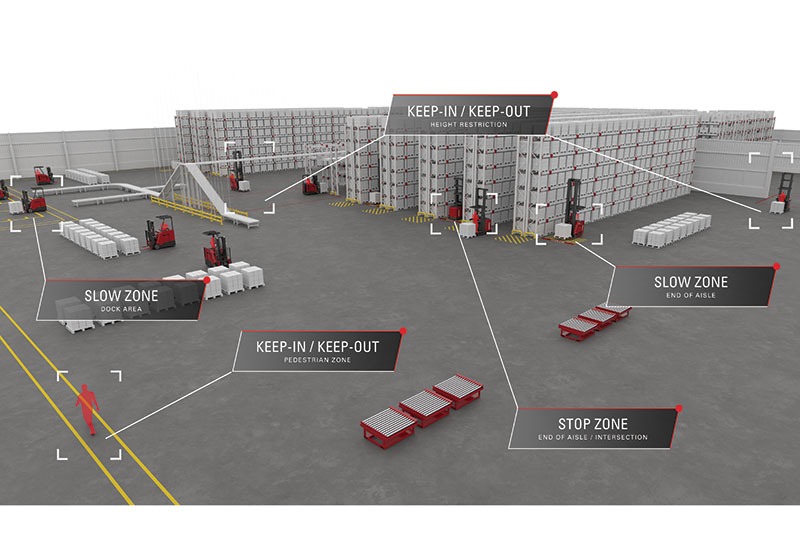

“The adoption of telematics has been pretty important to tracking incidents and being able to identify who the operator of the truck was at the time of the incident,” Gaskell says. “If you add some location tracking technology to telematics, you can now determine where the incident occurred and also set speed thresholds for specific areas of an operation.”

Meanwhile, object detection technology for lift trucks has improved, with LiDAR sensors able to spot objects within the sensor’s field of view. Ultra-wideband (UWB) anchors can be placed on infrastructure such as ceilings, posts or columns. UWB tags can be placed on forklifts and integrated into employee badges to provide for added object detection and localization capabilities.

These technologies, Gaskell adds, are meant to assist operators by warning them to make safe decisions. In some cases, if a collision or incident is imminent, today’s technologies can actively slow the vehicle.

粤公网安备 44010602003952号

粤公网安备 44010602003952号